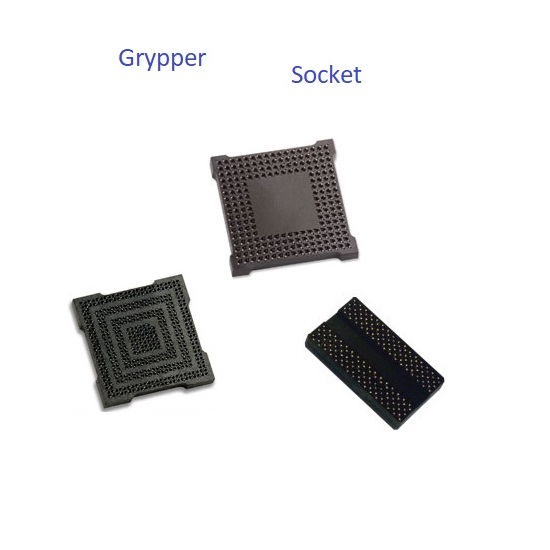

Grypper Debug Socket

design and manufacture new Grypper test sockets for eMMC and UFS BGA devices.

The Grypper sockets support the variety of sizes that 153 ball eMMC and UFS devices are produced, ranging from 7.5 x 7.5 mm to the 11.5 x 13.0 -0.50 pitch size.

FCS-KLD Grypper socket, part number FCS1135-XXXX, was designed for the new UFS 4.0 form factor of 153 BGA 11.0 x 13.0 – 0.50 pitch. To connect a device, simply insert the device into the socket by pressing on top of the device, no lid is required. The unique geometry of the contact grips onto the solder balls of the device. To remove the device a simple extraction tool can be used to pop the device back out of the socket and it is ready to install another device. This Grypper socket has excellent electrical performance of – 1dB insertion loss greater than 25.0 GHz. Force required to insert a device is only 25 grams / contact. The socket is sold in three configurations; sockets with a Rohs solder ball (SAC 305) replicates the device. The socket configured with SnPb solder balls allow easy reflow/attachment onto a PCB that already has components mounted. The lower melting temperature of the SnPb solder will not affect any adjacent components that might be close to the target area where the socket is to be placed. The socket can also be purchased with No solder balls. No solder ball version requires the use of a 0.2mm thick stencil for the correct amount of solder paste allowing any type of solder paste the customer’s lab might use for attachment.

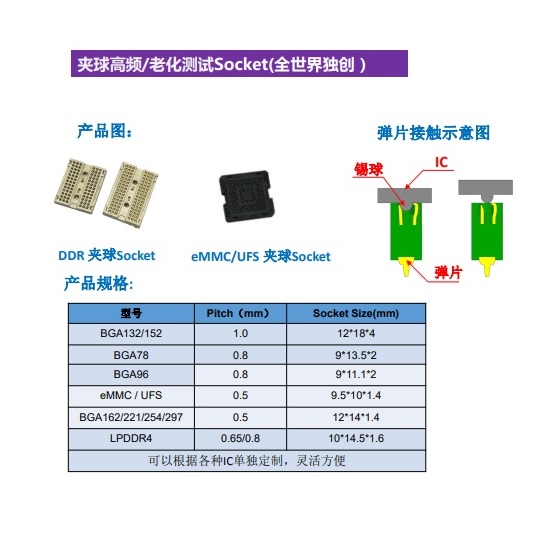

Product specifications:

1. Application IC: 1.27/1.0/0.8/0.5 BGA package

2. Material: PEI/nickel alloy/beryllium copper

3. Contact method: welding shrapnel

4. Working temperature: -45°C~+125°C

5. Working life of more than 500 times

Features:

1. The appearance structure adopts open mold, which not only ensures accuracy but also reduces cost;

2. Small size, no interference with surrounding components, suitable for any plate shape

3. Easy to use, solder on the IC position corresponding to the PCBA board to be used.

Press in according to the direction to perform relevant tests.

4. The contact shrapnel is shorter, reducing the signal transmission distance between the chip and the original PCBA.

Support high frequency testing

5. Using solder ball positioning, compatible with IC testing of various sizes

6. Can be customized individually according to various ICs, flexible and convenient