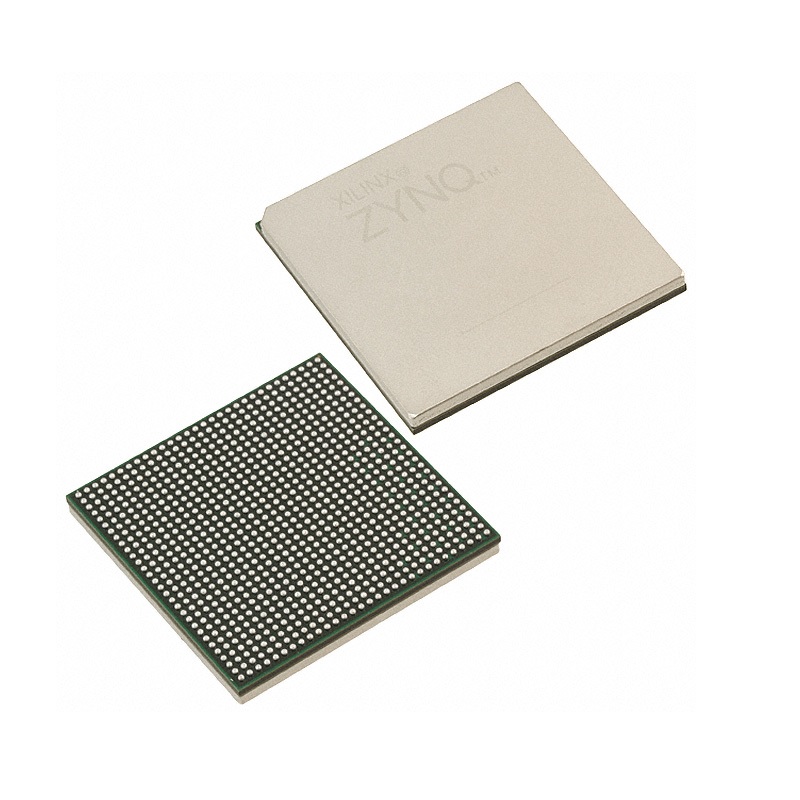

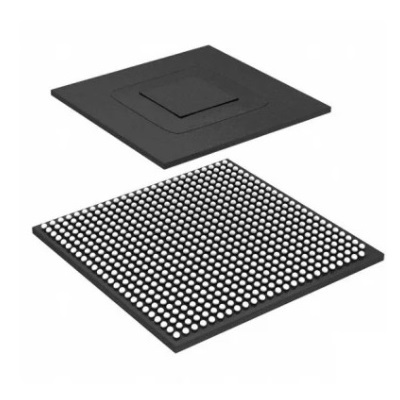

BGA900 embedded FPGA chip XC7K410T-2FFG900I

1. Actual requirements:

1).Package: BGA package

2).Pin number: 900pin

3). Spacing: 1.0mm

4). Chip type: FPGA chip

5).Testing requirements: chip functional debugging, programming and mass production

2. Requirements analysis: After the chip is burned, FPGA needs further performance verification. After verification, reliability testing needs to be done. Reliability testing includes HAST test and HTOL test; it needs to meet dynamic high and low temperature tests, mainly during aging. This test is completed by energizing the furnace.

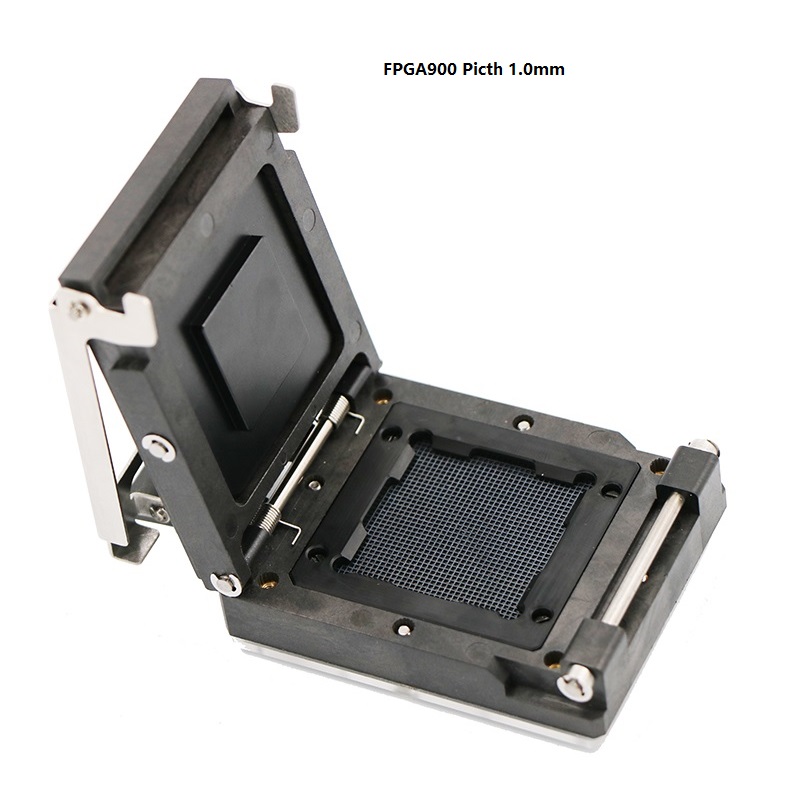

3. Production: The chip is a semi-customized product, and the main structure is an open-molded product. It is manufactured according to a fixed spacing. You only need to customize the corresponding limit, top heat dissipation structure and lower probe.

4. During the production process, each customized component is strictly inspected to confirm that the structure of the chip is within the allowable range. Only after all components are confirmed to be ok can they be assembled, and the overall inspection is completed before shipment.